Coiled Spring Pins

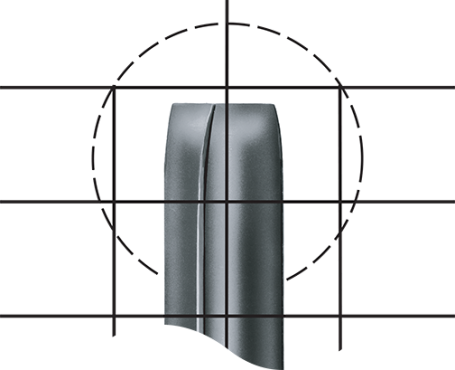

SPIROL invented the Coiled Spring Pin and its production technology in 1948. Since that time, the Coiled Pin has proven to be the most versatile Spring Pin in the industry. Easily recognized by its unique 2 1/4 coil cross-section, Coiled Pins are self-retaining fasteners achieved by radial tension applied against the hole wall, and they are the only press-fit pins designed to remain flexible after installation. More than fasteners, SPIROL Coiled Pins are shock-absorbing elements that are integral, active components of a total assembly. Coiled Spring Pins are available in three duties, light duty, standard duty and heavy duty, to enable the designer to select the right combination of strength, flexibility and diameter to suit different host materials, strength requirements and loading types. SPIROL Coiled Pins typically offer the lowest installed cost in most applications.

Otherwise known as Spiral Pins, Coil Pins, Roll Pins or simply Spring Pins, SPIROL offers Coiled Spring Pins in both inch and metric sizes in a variety of materials and finishes from 0.8mm / .031” (1/32) in diameter up to 20mm / .750” (3/4) in diameter. Select from our expansive standard offering, or take advantage of our complimentary Application Engineering support and allow us to work with you to help determine the most appropriate Coiled Pin for your specific application and assembly needs!

If installation equipment is required, SPIROL also offers a standard comprehensive line of Pin Installation Equipment from manual to fully automatic modules, with or without out fixturing, to support your Coiled Pin assembly requirements.

Coiled Spring Pin Types

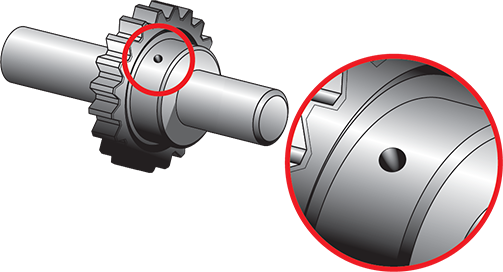

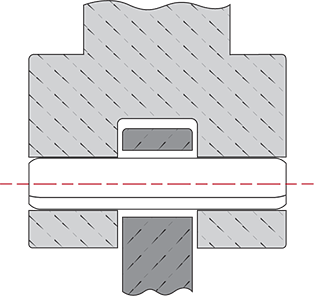

Coiled Spring Pins are commonly used as hinge pins and pivots, for locating and alignment, attaching a gear to a shaft / collar, and for fastening two or more components together.

SPIROL offers Coiled Spring Pins in three different duties, light duty, standard duty and heavy duty, to match the required strength and flexibility for each application. A pin too strong for the applied force will not flex and can cause damage to the hole. A pin too flexible could prematurely fatigue in the application. The Coiled Pin with the optimal combination of strength, flexibility and diameter will result in the prolonged useful life of an assembly. Generally speaking, light duty Coiled Pins are used in plastic and other soft, brittle or thin materials, standard duty Coiled Pins are used in mild steel and non-ferrous host materials, and heavy duty Coiled Spring Pins are used in hardened materials where space prohibits the use of a larger diameter standard duty pin.

SPIROL also offers a selection of Coiled Pins designed for common application-specific requirements such as cosmetic cases, key fobs, head rests, transmissions, card locks and ejector clips. If one of SPIROL's standard Coiled Spring Pins does not meet your needs, our Application Engineers will work with you to design a custom Coiled Pin to meet your unique requirements.

Select from the options below for more specificity about SPIROL's Coiled Pin offering or contact us for complimentary technical support!

Don’t See What You’re Looking For?

Need help choosing the most appropriate fastening solution for your application? SPIROL's expert engineers will review your specific requirements, and design the most cost-effective Coiled Spring Pin to meet your technical and commercial needs. Let us help!

Specifications

| Pin Duties | Material Type | Material Grade | Hardness, Vickers | Finishes |

|

M Standard

H Heavy L Light |

B High Carbon Steel | UNS G10700 / G10740 C67S (1.1231) / C75S (1.1248) |

HV 420 - 545 |

K Plain, Oiled

T Electroplated, Zinc |

| W Alloy Steel | UNS G61500 51CrV4 (1.8159) |

HV 420 - 545 | ||

| D Stainless Steel, Austenitic (Nickel) | UNS S30200 / S30400 18-8 (1.4310) |

Work Hardened | ||

| C Stainless Steel, Martensitic (Chrome) | UNS S42000 X30Cr13 (1.4028) |

HV 460 - 560 |

TO ORDER: Product Code / Diameter / Length / Duty / Material / Finish

EXAMPLE: CLDP 8 X 32 MBK

Unique Features & Benefits

Only Coiled Pins utilize the coiled spring concept; a recognized superior pin design. This imparts to SPIROL Coiled Spring Pins unique features not found in other Spring Pins or Solid Pins. More than fasteners, SPIROL Coiled Pins are shock-absorbing elements that are integral, active components of a total assembly. There are other pinning methods, but when the total assembly's manufacturing cost, quality and useful life are important, the pin of choice is the SPIROL Coiled Spring Pin.

Features Include:

- Absorbs Shock and Vibration

- Uniform Strength and Flexibility

- Equal Stress Distribution

- Swaged Chamfers

- Square Ends

Other Advantages:

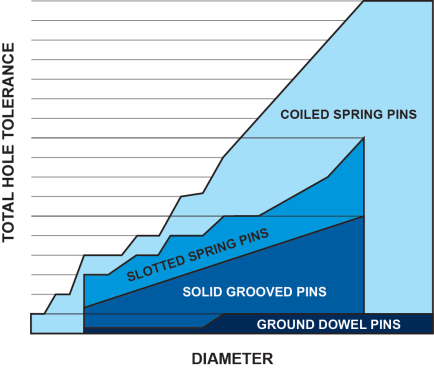

- Closer Diameter Tolerances

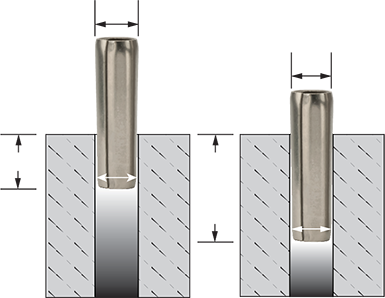

- Conforms to Hole

- Lower Insertion Pressure – Radial Tension

- Wider Range of Duties, Diameters and Materials

- Wider Hole Tolerance Range

- Straightness

- Automatic Feeding

- Reusable

Design Guidelines

SPIROL provides general design guidelines and complimentary Application Engineering support to help you design your assembly to achieve the desired form, fit and function for the life of the product.

Common Coiled Pin Applications Include:

- Hinge Pins / Pivot Pins

- Fastening Pins

- Locating Pins / Alignment Pins

- Pinning a Gear to a Shaft

- Stop Pins

- Flow Restriction

- Reinforcement Within Plastic

Take advantage of SPIROL's complimentary Application Engineering support to help you select the proper Coiled Pin to meet both your application and assembly requirements.

Installation Technology for Pins

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of Pin Installation Equipment designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automated work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Application Success Stories

Retaining Pin in Hydraulic Poppet Valve / Solenoid Valve

Customer Challenge:

A leading manufacturer of hydraulic poppet valves request support from SPIROL Engineering to recommend a pin to retain a check ball within a valve assembly subject to longitudinal shock forces.

SPIROL solution:

- SPIROL Engineering recommended that a Coiled Spring Pin be installed perpendicular to the check ball to prevent the ball from coming loose.

- The unique characteristics of the Coiled Pin provided the flexibility needed to absorb the shock loads balanced with sufficient strength to withstand the forces generated within the assembly.

- SPIROL's Coiled Spring Pin met all performance criteria required by the customer and resulted in component and manufacturing cost savings versus the more traditional (and expensive) fastening method of using a threaded collar coupled with a threaded fastener.

- In addition to recommending the most cost-effective retaining pin, SPIROL's Application Engineering team also recommended the appropriate hole sizes, engagement length, material type, and finish to ensure the assembly functioned properly.

Reinforcement for Plastic Fuel Evaporation Canister

Customer Challenge:

A manufacturer of fuel systems requested SPIROL's help in reinforcing the hose fitting area of their new plastic evaporation canister. The reinforcing component had to be self-retaining, resistant to the harsh corrosive environment, and allow fumes to flow freely through its center.

SPIROL solution:

- After a comprehensive application evaluation, SPIROL Engineering recommended the use of a stainless steel light duty Coiled Spring Pin.

- The light duty Coiled Pin is self-retaining, yet unlike the Slotted Pin, the light duty Coiled Pin does not exert excessive force that could damage the plastic tube.

- A 302/304 stainless steel light duty Coiled Spring Pin eliminates the risk of corrosion, and the thin layers of wrapped stainless steel provides the largest inner diameter of any standard Spring Pin. This allows maximum functional volume for fume flow through the center of the pin.

- The spring properties of the light duty Coiled Pin provide ample structural integrity; while the associated flexibility keeps the plastic host from cracking or deforming.

Retaining Pin for Stage Lighting & Truss Assemblies

Customer Challenge:

A manufacturer of truss systems used for stage lighting and stadium seating approached SPIROL for help selecting the right fastener to retain extruded aluminum tubing to the couplers. The fastener would often be subjected to shock, vibration and the assembly had high strength requirements.

SPIROL solution:

- SPIROL Engineering recommended a 420 stainless steel Coiled Spring Pin for its combination of superior strength and corrosion resistance.

- Since Coiled Spring Pins remain flexible after installation, they absorb dynamic loading and protect the integrity of the hole to ensure retention within the truss assembly.

- Coiled Pins do not have to be oriented for strength like other Spring Pins, so the direction of the high loads is immaterial.

- Coiled Spring Pins can be removed from the hole without damage to the assembly. The same pin may be reused in the same hole. This enables the truss to be assembled and disassembled for use at different venues.

- Implementation of SPIROL's recommended Coiled Pin met all of the manufacturer's performance and commercial requirements and ensured ongoing integrity of the truss assembly.

Drive Pin Within Laproscopic Surgical Device

Customer Challenge:

A medical device manufacturer requested SPIROL’s assistance to eliminate high insertion forces, pin bending, component damage and generation of metallic debris that they experienced with a CNC-machined Knurled Solid Pin. Metal shavings are completely unacceptable since the surgical device goes inside the human body.

SPIROL solution:

- SPIROL Engineering determined that the root cause of the high insertion forces, pin bending, damage to the subassembly and generation of metallic debris was due to variation of the rigid Solid Pin's diameter coupled with the knurls shaving off of the unhardened 303 stainless steel Knurled Solid Pin as it was installed into a hardened 416 stainless steel shaft.

- SPIROL recommended replacing the Solid Pin with a heat treated, 420 stainless steel Light Duty Coiled Spring Pin to provide the balance of strength and flexibility for this laparoscopic surgical device.

- The flexibility of Coiled Pin facilitates a low insertion force while providing adequate retention without protruding knurls damaging the hole and generating debris

- The hardened 420 stainless steel Coiled Pin provided the necessary corrosion resistance without risk of being damaged during insertion into the 416 stainless shaft.

- By replacing the machined Solid Knurled Pin with a Light Duty Coiled Spring Pin, the medical device manufacturer reduced their costs and permanently resolved all of the issues previously experienced with the Solid Pin.

Tamperproof Retaining Pin in Molded Plastic Spray Bottle Nozzle

Customer Challenge:

A manufacturer of molded plastic spray bottle nozzles used in restaurants requested SPIROL’s help to “tamperproof” their adjustable spray tip so that the spray volume could not be adjusted resulting in too much or little solution applied.

SPIROL solution:

- SPIROL's Engineers determined that the hole through the nozzle assembly could be created by using a pin to pierce the plastic during installation.

- The swaged chamfers on SPIROL’s Coiled Pin make an ideal reduced diameter for piercing a plastic hole, while the larger body diameter of the Coiled Pin retains itself securely within the assembly.

- The nozzle caps arrive to SPIROL's Model PR Pin Inserter pre-adjusted for the proper piercing location. The operator loads the components into the fixture and activates the machine to install the pin. No machine adjustments are required during installation.

- The installed Coiled Pin provides rotational resistance and prevents the end user from adjusting the spray volume – making it tamperproof!

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+1 519 974 3334

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国