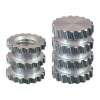

Press-In

Press-In Inserts are designed to be pressed into a straight hole without melting the plastic prior to installation. Ideal for use in softer plastics, the helical knurls of the Press-In Inserts are used to provide both torque and pull-out resistance and to ensure good plastic flow as the Insert rotates into the hole. Installation torque to achieve sufficient tension between the threads is not a problem in that the helical knurls are designed so that the direction of the installation torque will have the tendency to drive the Insert into the hole — which of course is not possible — as the threaded joint is tightened. A pilot only slightly smaller than the hole and of sufficient length is designed to assure straight insertion into the hole. Press-In Inserts offer rapid installation with no specialized equipment and achieve good overall joint performance.

If installation equipment is required, SPIROL also offers a standard comprehensive line of Insert Installation Equipment from manual to fully automatic modules, with or without out fixturing, to support your Threaded Insert assembly requirements.

Application Engineering Assistance: If you would like assistance in selecting the proper Threaded Insert for your plastic assembly, please Request Engineering Support! We are here to help!

Press-In Threaded Inserts Product Listing

Press-In Insert

The Series 50 Press-In Insert is provided with generous pilots on each end to facilitate installation into the hole. Given that the Series 50 is a symmetrical Insert, orientation of the Insert prior to installation is not required. Series 50 Press-In Inserts are available in both metric and inch thread sizes ranging from M2 (2-56) up to M8 (5/16-18)

Headed Press-In Insert

Series 51 Headed Press-In Insert is the headed version of SPIROL's Series 50 Insert. The Series 51 Press-In Insert is provided with a generous pilot on the end opposite the head to facilitate installation into the hole. The addition of the head provides additional bearing surface for the screw, and also makes it suitable for pull-through applications where high tensile (pull-out) force is required. Series 51 headed Press-In Inserts are available in metric thread sizes ranging from M2 to M8 and unified thread sizes ranging from 2-56 to 5/16-18.

Additional Threaded Insert Types

Customizable Solutions

If you are unable to find the Threaded Insert in the thread size, length, material, finish or quantity that you require within our standard offering, or if you are unsure what Insert is most appropriate for your plastic assembly, Request Engineering Support and we will help you find the most cost-effective solution for your application.

Installation Technology for Threaded Inserts

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of Installation Equipment for Threaded Inserts for Plastics specifically designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automated work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+1 519 974 3334

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国