Additional Options

You can rely on SPIROL to be a design partner to help solve unique problems. Because we supply numerous customers with similar products in similar industries, we are able to meet most needs with our standard products at no additional cost. When the solution falls outside the normal requirements, we have the expertise and engineering personnel to solve those problems. By working with you at the design stage, we will develop a solution that lowers your overall product cost, improves product quality, increases the robustness of your manufacturing process, and gets you to market faster.

When reviewing your application, SPIROL’s Application Engineers will first attempt to use a standard product to meet your technical requirements as this offers the most affordable solution and will reduce your total manufacturing cost.

During our engineering review, if a standard Solid Pin cannot meet your application or assembly requirements, our Engineers will design a special pin to meet your needs. Many specials are derivations of our standard products and can be produced with minimal investment in development. Others are completely unique and may require a larger investment in development or special processing on our CNC machinery.

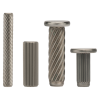

As an example, while SPIROL's standard Knurled Pins have a knurl that spans the full length of the pin, it is sometimes necessary for the purpose of assembly, retention or function to modify the knurl length or location on the pin. SPIROL's Application Engineers are available to assist you in the design of a custom Knurled Pin to meet your specific application requirements.

Application Engineering Assistance: If you would like assistance in selecting or designing the proper Pin for your application, including obtaining the critical recommendations for hole sizes and tolerances, please Request Engineering Support! We are here to help!

Special Sizes

SPIROL can manufacture special configured Solid Pins and large diameter special Solid Pins in low volumes up to Ø19mm (Ø.750”) in diameter and 75mm (3”) in length.

Special Surface Configurations

SPIROL can manufacture Solid Pins with multiple diameters, grooves, knurls, threads, elongated chamfers, heads, center holes, side holes, as well as those that are turned, shaved, burnished, broached, back drilled, and counterbored.

The location and length of the knurls and barbs can be positioned anywhere along the body of the pin to accommodate application-specific requirements.

Special Materials

In addition to the standard materials,, SPIROL’s production technology enables us to produce Solid Pins out of a variety of materials. The most common alternate materials are:

- Alloy steel

- Aluminum

- Brass

- Martensitic Stainless Steel

Special Finishes

SPIROL Engineers have extensive experience in recommending the right combination of materials and finishes to meet application-specific requirements.

Additional Solid Pin Types

Customizable Solutions

If you are unable to find the Solid Pin in the diameter, length, material, or finish that you require within our standard offering, or if you are unsure what Pin is most appropriate for your assembly, Request Engineering Support from our team and we will help you select the most cost-effective solution for your application.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+1 519 974 3334

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国